Metals

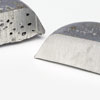

Seyekcub's state of the art metal degassing and oxide removal process provides castings with superior visual and mechanical properties.

Seyekcub's state of the art processes provide castings with superior mechanical properties due to gas elimination and oxide removal. Seyekcub pours castings from several ounces to over 700 pounds. Some of the alloys we pour are 356, A356, 319 and 713

High quality ingot to meet customer specifications